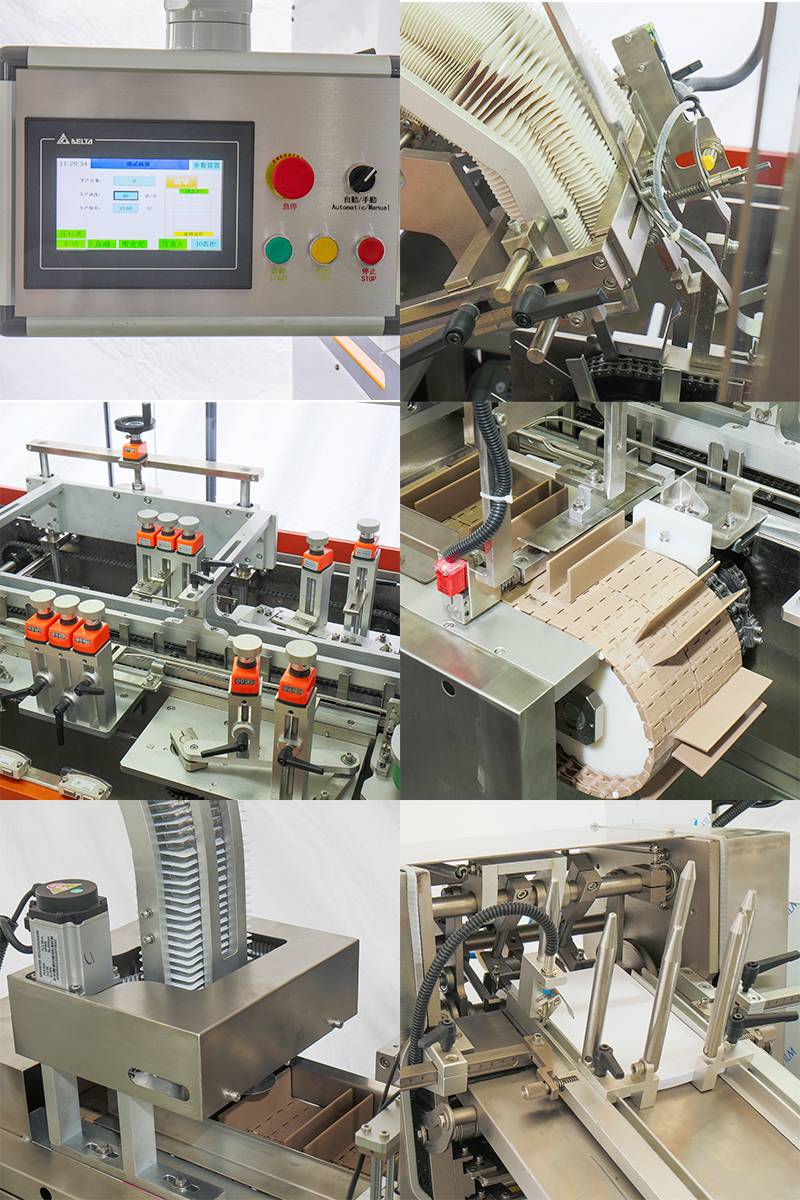

NBR-130 Hong Kong version automatic boxing machine

机器细节图:

Machine Introduction:

This device is a new model developed by our company in combination with advanced technologies at home and abroad, integrating optics, electricity, gas, and machinery into a high-tech product. As a result, the performance and work efficiency of the equipment have been significantly improved, meeting the requirements of fast packaging and maintaining a stable and reliable state during rapid operation.

This model is suitable for automatic feeding and boxing of multiple varieties and specifications (can also be bottled or packed with aluminum-plastic panels) of items. The feeding mechanism is easy to adjust and the number of plates to be packed can be set arbitrarily on the operation screen. The entire process of online material conveying and testing, optional manual folding (optional; 1 to 4 folds and transfers), material entering the box, batch number printing, paper tongue packaging at both ends of the box (also applicable to hot melt adhesive), missing material removal, and finished product output are all automatically completed.

Packing characteristics:

A. Reasonable structure, smooth transmission, and low noise;

B. Good packaging quality, square and beautiful appearance;

C. Having a comprehensive detection system and safety protection devices, sufficient to ensure packaging quality and operational safety;

D. Human computer interface operation, easy to set and use, reliable and stable;

E. Suitable for a wide range of objects, easy to install and adjust.

Machine parameters:

Packing speed 40-80 boxes/minute (depending on the size of the paper box) | ||

Carton | quality requirement | 300-350g/㎡【Depending on the size of the cardboard box】 The indentation depth of the paper box fold line should not be less than 0.8 times the thickness of the paper; The paper box indentation must be pre folded at 120 °, making it easy to manually open the box and ensure that the paper box is easy to open and form; The direction of paper texture should be correct and in the same direction, parallel to the same direction edge, without diagonal or multi-directional texture. |

Size range(L×W×H) | (70-180)mm×(20-85)mm×(15-70)mm (Product specifications and dimensions have changed and require mold replacement) | |

compressed air | Working pressure | 0.6-0.8Mpa |

Gas consumption | 120-160L/min | |

power supply | 220V 50HZ | |

Main motor power | 1.5kw | |

External dimensions(L×W×H) | 3100㎜×1400㎜×1750㎜(Refer to the drawing for details) | |

Net weight of the whole machine | 约800kg(Refer to the drawing for details) | |

Main configuration:

Serial Number | type | name | brand | notes |

1 | ECU | PLC | Delta/Xinjie | Taiwan/Wuxi |

2 | HMI | Delta/Kunlun communication status | Taiwan/Shenzhen | |

3 | frequency converter | Delta/Furuiken | Taiwan/Shenzhen | |

4 | Circuit breaker 3P | 施耐德/德力西 | France/Zhejiang | |

5 | Circuit breaker 1P | 施耐德/德力西 | France/Zhejiang | |

6 | Contactor | 施耐德/德力西 | France/Zhejiang | |

7 | Intermediate relay | Omron | Japan | |

8 | Relay module | Omron | Japan | |

9 | switch power supply | Delta/Mingwei | Taiwan | |

10 | Photoelectric switch | Omron | Japan | |

11 | proximity switch | Omron | Japan | |

12 | Power cut-off switch | the Yangtze River | China | |

13 | EMERGENCY STOP | schneider | France | |

14 | switch button | schneider | France | |

15 | encoder | Omron | Japan | |

16 | aerodynamic | solenoid valve | AirTAC | Taiwan |

17 | Vacuum generator | Zeta Horino | Taiwan | |

18 | Pressure regulating valve | AirTAC | Taiwan | |

19 | electrical machinery | Yongkun | China | |

20 | Linear sliding rail | HIWIN | Taiwan | |

21 | bearing | Harbin | China |

- Cartoning machine : NBR-130 Hong Kong version automatic boxing machine 2025-04-18 21:40

- Cartoning machine : Anti disassembly paper box automatic forming and packaging integrated machine 2023-09-06 11:17

- Cartoning machine : NBR-ZH-80 automatic boxing machine 2023-09-06 11:17

- Cartoning machine : NBR-200 fully automatic food spray packaging machine 2023-09-06 11:17

- Cartoning machine : NBR-200A Multi row Bag Packaging Machine 2023-09-06 11:17

- Cartoning machine : NBR-120 fully automatic box loading machine 2023-09-06 11:17

- Cartoning machine : NBR-300 pillow type automatic box loading machine 2023-09-06 11:17

- Cartoning machine : NBR-300L pillow type automatic box loading machine 2023-09-06 11:17

- Cartoning machine : NBR-130 automatic box loading machine 2023-09-06 11:17

- Cartoning machine : NBR-50 vertical packaging machine 2023-09-06 11:17

- Cartoning machine : NBR-300A fully servo automatic boxing machine 2024-03-14 14:49

- Cartoning machine : NBR-ZH-260 fully automatic high-speed box packing machine 2024-04-30 16:22

- Cartoning machine : NBR-130 Hong Kong version automatic boxing machine 2025-04-17 14:10