What are the common faults of fully automatic high-speed box loading machines? How should we solve it?

To choose a good packaging machine, the first step is to choose a reliable manufacturer. After all, expensive products may not necessarily be the best, but being suitable for oneself is the most important. So how do you know if a packaging machine manufacturer is reliable? Today I will tell you how to choose a reliable packaging machine manufacturer.

To choose a good packaging machine, the first step is to choose a reliable manufacturer. After all, expensive products may not necessarily be the best, but being suitable for oneself is the most important. So how do you know if a packaging machine manufacturer is reliable? Today I will tell you how to choose a reliable packaging machine manufacturer.

1. We will first check with the manufacturer to see if they have the packaging machine they need and if it meets their needs, and then see if it can be customized, provided that our cardboard box parameters are greater than or less than the parameter values provided by the manufacturer.

2. Looking at the manufacturer's address, everyone knows that manufacturers in first tier cities are generally better than those in third or fourth tier cities. Not to mention anything else, let's just talk about salaries in first tier cities. High salaries attract talent, and talented manufacturers have the real strength to improve their technical level.

3. Judging by the reputation of a manufacturer, reputation is very important for a manufacturer. However, don't ignore its reputation because its equipment is cheap. It's worth spending money, and the manufacturer's annual sales revenue. The quality of a factory's equipment depends on its sales revenue, after all, good equipment can only be sold well.

4. Check if the factory includes delivery and installation. Many packaging machine manufacturers have cooperative relationships with logistics, and it is more cost-effective to have manufacturers assist in transportation than to find a logistics company on their own; Some customers think that their installation technology is very good, but in our opinion, it is "Zhu Bajie eats Ginseng fruit without knowing its taste". Some subtle things can't be done without professionals.

5. Check the after-sales service. Some manufacturers may encounter problems with your equipment after shipping, and when you contact them, they may be indifferent to you, or the after-sales service time may be short, not including after-sales service. So we must find a manufacturer with an after-sales service team that can provide on-site repairs.

6. Finally, when looking at the contract payment, it is important to pay attention to those manufacturers who have fully paid for the shipment. Engineering workers should know that there is a final payment. If there is a problem with the equipment within the specified time, the manufacturer should be fully responsible. Don't be fooled into paying the full amount in one go. If there is a problem with the equipment, you won't even have room to cry.

The above are the main factors for choosing a reliable packaging machine manufacturer, hoping to help you. Welcome to inquire more questions.

What are the common faults of fully automatic high-speed box loading machines? How should we solve it? (1)

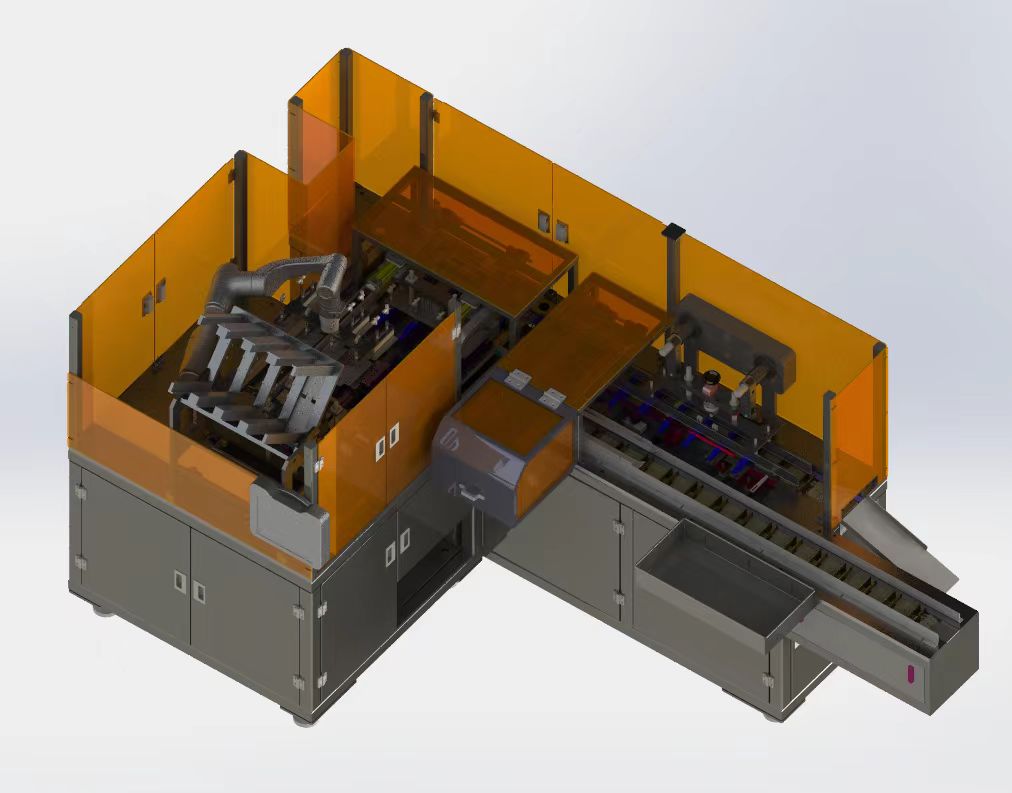

The fully automatic high-speed box loading machine is a fully automatic and continuous packaging molding machine with high box loading speed. Today, I will take you to learn about the common faults of fully automatic high-speed box loading machines and how to solve them.

1. The paper box of the fully automatic high-speed packaging machine cannot be successfully sucked

① Check if the suction cup in the suction box mechanism is damaged or aged

Solution: Replace the suction cups in a timely manner.

② Check if there is any blockage or leakage in the vacuum pipeline

Solution: Carefully check the circuit and air circuit, and eliminate faults

③ The suction box action of the paper suction mechanism is incorrect:

Solution: Adjust the position and time of the conveyor chain according to the sum.

④ Paper boxes sticking together:

Solution: Replace the paper box.

2. When the manual of the fully automatic high-speed box loading machine cannot be extracted

① The suction nozzle did not contact the instruction manual

Solution: Follow the adjustment method to readjust the position and angle of the suction nozzle and the paper tray.

② The contact instructions for the suction nozzle indicate that there is no vacuum generated

Solution: Re adjust the instructions for vacuum production time based on the adjustment method.

③ Insufficient suction of the suction nozzle

Solution: Check if there is any leakage or blockage in the vacuum pipeline of the machine and troubleshoot it.

④ Incorrect adjustment of the transmission mechanism system in the manual mechanism

Solution: Follow the steps in the manual to readjust.

⑤ The action of the paper separation mechanism is incorrect, and the action and time of the blowing mechanism are incorrect

Solution: Follow the adjustment steps in the manual to readjust.

3. The suction nozzle of the fully automatic high-speed box loading machine draws multiple instructions

① The angle of the paper tray is not appropriate

Solution: Re adjust the position angle between the paper tray and the suction nozzle.

② The last to last instruction manual was not separated

Solution: Readjust the matching between the paper separation structure and the action of the suction nozzle.

4. The instruction manual is left inside the origami mechanism

① The gap between the folding rolls in the folding mechanism is not suitable

Solution: Readjust the gap between each origami roller.

② The paper roller damaged the manual and got stuck in the folding mechanism

Solution: Adjust the matching between the paper roller and the paper separation structure, as well as between suction and blowing.

The above are the main factors for choosing a reliable packaging machine manufacturer, hoping to help you.

- Company News : What are the common faults of fully automatic high-speed box loading machines? How should we solve it? 2023-09-06 10:56

- Company News : How to choose a reliable packaging machine manufacturer 2023-09-06 10:56

- Company News : What is the packaging process of multi column vacuum food 2023-09-06 10:56

- Company News : The functions and advantages of the side push opening and sealing integrated machine! 2023-09-06 10:56

- Company News : What are the classifications of packaging machines? 2023-09-06 10:56

- Company News : What kind of equipment is replacing manual handling and palletizing - an automatic palletizer 2023-09-06 10:56

- Company News : What is the fastest efficiency of the unboxing machine? 2023-09-06 10:56

- Company News : Cigarette cartridge packaging machine NBR electronic atomizer packaging machine packaging machine assembly line after packaging the entire line 2023-09-06 10:56

- Company News : What are the main forms of packing machines? 2023-09-06 10:56

- Company News : What problems will be encountered during the use of aluminum plastic packaging machines? 2023-09-06 10:56

- Company News : What are the factors that affect the blister effect? 2023-09-06 10:56

- Company News : Characteristics/working principle of automatic folding and sealing machine 2023-09-06 10:56