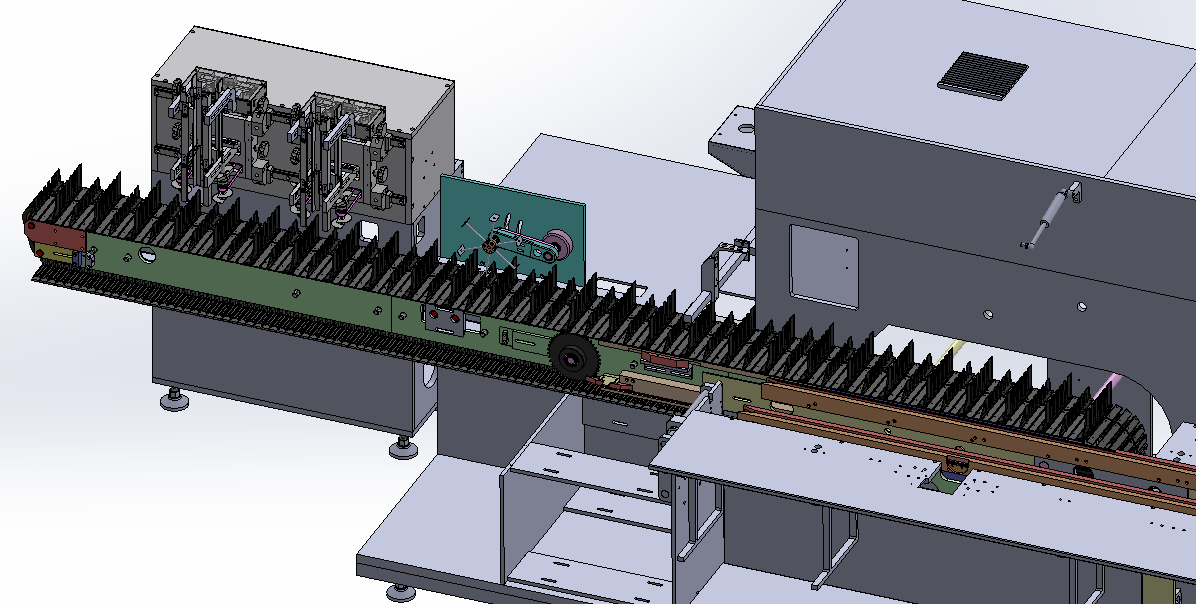

NBR-ZH-260 fully automatic high-speed box packing machine

NBR-ZH-260型全自动高速装盒机NBR-ZH-260 fully automatic high-speed box packing machine

The ZH-260 fully automatic high-speed packaging machine is a model that our company innovatively designed based on the introduction of advanced foreign technology, and is manufactured strictly in accordance with the GMP requirements of the pharmaceutical industry. Having high efficiency and performance production capabilities, the folding and conveying of instructions, paper box forming, and rear pushing mechanism related technologies meet European and American standards; The concise appearance design and continuous feeding structure at the rear make operation and maintenance more convenient; Triple split double planetary wheel rotating outward opening box and equipped with two pre forming devices to ensure the complete opening and forming of the paper box. This machine is a fully automatic continuous high-speed box packing machine, which integrates machine, light, electricity, and gas for high-performance products. It is suitable for automatic box packing of aluminum-plastic blister boards, bottles, hoses, soft double aluminum, and bag shaped items, and can be matched with it to form a packaging production line.

1. No product or instruction manual, no paper box without instruction manual;

2. When there is no product or the product supply is not in place, the machine will idle and not push the product. When the product supply is restored, it will automatically run, and if the product is not in place, it will automatically shut down;

3. Automatic shutdown without paper box, and automatic shutdown without manual for multiple consecutive times;

4. Shutdown alarm for low compressed air and vacuum negative pressure;

5. The rear pushing mechanism can leave more space on the front of the machine, making it more convenient and user-friendly for operators to operate and maintain the machine;

6. The dial scale handwheel allows for very simple product specification replacement;

7. The main transmission has an overload protection device to ensure the safety of the machine and operation;

8. Servo feeding system: The feeding device adopts a swing tracking method for feeding; Compared with similar fixed feeding devices on the market, it has faster speed and more accurate feeding; It is possible to transfer one piece of material at a time or multiple pieces of material at a time to the material conveying chain plate slot.

9. The main motor, PLC, frequency converter, sensors, relays, contactors, and pneumatic components are all internationally renowned brands;

10. Automatically display packaging speed, alarm faults, and counts.

The frame of this machine is welded with channel steel and square steel plates. The transmission of each component of the machine is installed on the bottom plate of the frame. The rear wall panel and middle wall panel are fixed above the substrate. The mobile wall panel is suspended above the base frame by several sliding axes and screw rods, which can move forward and backward under the action of the screw rods, so that it can be adjusted according to the size of the paper box for different users. The box conveyor chain guide rail is installed on the front and middle wall panels, which is not only a protective device for the paper box conveyor chain, but also a bracket for the paper box to move. The origami machine base is fixed to the bottom plate of the frame. There are vacuum pumps, main motors, and pneumatic components installed inside and above the rack. When the machine is working alone, it can be controlled on the human-machine interface (touch screen) to run/stop the host, as well as to turn on/off the vacuum pump.

2. Performance and working principle

2.1 Rack

The frame of this machine is welded with channel steel and square steel plates. The transmission of each component of the machine is installed on the bottom plate of the frame. The rear wall panel and middle wall panel are fixed above the substrate. The mobile wall panel is suspended above the base frame by several sliding axes and screw rods, which can move forward and backward under the action of the screw rods, so that it can be adjusted according to the size of the paper box for different users. The box conveyor chain guide rail is installed on the front and middle wall panels, which is not only a protective device for the paper box conveyor chain, but also a bracket for the paper box to move. The origami machine base is fixed to the bottom plate of the frame. There are vacuum pumps, main motors, and pneumatic components installed inside and above the rack. When the machine is working alone, it can be controlled on the human-machine interface (touch screen) to run/stop the host, as well as to turn on/off the vacuum pump.

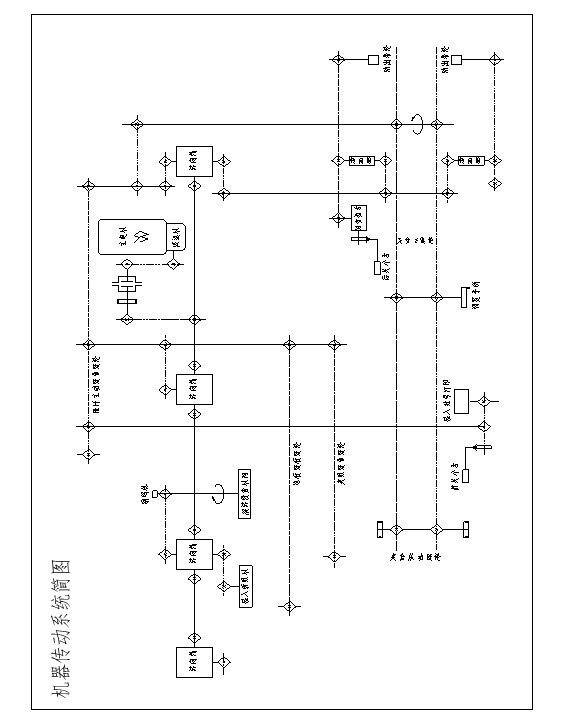

2.2 Main transmission system

This section is located inside the rear of the rack, and each component is fixed to the bottom plate of the rack. By using a servo motor and synchronous wheel, transmission synchronous belt, clutch input synchronous wheel, and electromagnetic clutch (the electromagnetic clutch is in a suction state when powered on), the transmission shaft is connected to several steering gears for operation, with a simple structure and good stability. Each workstation is equipped with various steering gears and synchronous belt connections for control, which have high wear resistance, low noise, and no need for lubrication. It can effectively reduce equipment vibration during high-speed operation, increase the service life of equipment and components, greatly reduce labor intensity, and lower maintenance costs in the later stage.

2.3. Box transmission mechanism

The power is transmitted to this section by the servo motor power input wheel. During operation, sprocket assembly 1 and sprocket assembly 2 will drive the box conveyor chain to move forward, which can send the paper boxes absorbed by the suction mechanism to the pushing and sealing stations until the finished product is conveyed out of the conveyor belt. The box conveyor chain, also known as the paper box conveyor chain, is composed of four specially designed chains that run through the box conveyor chain tracks. The position of the four box conveyor chains can be adjusted by the relative positions of sprocket assembly 1 and sprocket assembly 2, so that products of different specifications and sizes can be packaged.

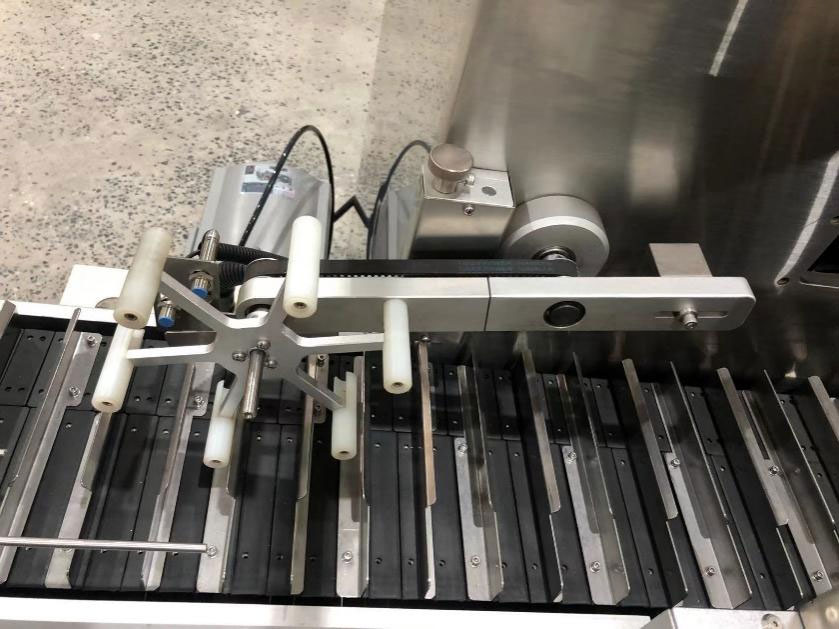

2.4. Drug Plate Conveyor Chain

This section mainly completes the cutting of medicine boards by the blister packaging machine, which are transported by the conveyor chain to the online medicine board stacking station. The number of medicine boards is controlled by the servo motor (which can be set on the touch screen). The chain of the medicine plate conveyor chain can be adjusted by loosening the adjustment screw and rotating the active sprocket of the conveyor chain, which can adapt to the width and size requirements of different customers and medicine plates.

2.5 Testing institutions

This section mainly detects the number of dosing plates. The power is transmitted to the main transmission shaft through the grid conveyor belt, and the internal structure of the detection component synchronizes the speed ratio between the synchronous wheels and belts to ensure that the detection action is consistent with the grid conveyor belt. Each grid is rotated by a detection rod to avoid cross collision. There are two photoelectric eye signals installed at the back of the detection system, which automatically detects multiple boards, few boards, and no boards. If there are multiple boards or few boards without boards, do not insert the instruction manual, do not insert the paper box, do not insert the correct number of medicine boards without instructions, do not insert the paper box, do not insert the correct number of medicine boards without instructions, and do not insert the correct number of medicine boards with instructions, and do not insert the paper box. When the pushing head does not move, the medicine board will be transported by the grid conveyor belt to the collection port and flow out, so that it can be recycled and reused without wasting paper boxes and instructions.

2.6 Pushing mechanism

The 23 head continuous pushing and feeding mechanism ensures the accuracy of material entering the box during high-speed operation when the box loading machine reaches a speed of 260 boxes, with a single head pushing speed of only 13 times/minute. The pushing and feeding action is gentle, effectively ensuring the accuracy of material entering the box during high-speed operation. At the same time, it can extend the service life of accessories and reduce operating costs.

Each group of push hands is in the form of double push hands, consisting of manual push hands and product push hands. The manual is pushed first and the packaging is pushed later to prevent the manual from causing resistance to the packaging.

When there is jamming or resistance overload, the moving rail can immediately retreat, triggering the overload protection photoelectric eye. The PLC will control the cylinder to work and push the moving rail backward, and immediately stop to ensure that some parts of the pushing hand are not mechanically damaged.

The opening and closing block of the pusher track is driven by a cylinder, and its main function is to retract the pusher without a medicine board or instruction manual back to the medicine pushing guide rail. The workstation without a medicine board or instruction manual does not push medicine.

2.7. Box suction and delivery mechanism

The suction box delivery mechanism mainly consists of the following parts: paper box conveying frame, box pressing device, rotating suction box device, and box opening device. Under the joint action of these parts, the cardboard boxes are extracted from the warehouse, opened, and placed on the cardboard box conveyor chain for transportation to the next process.

Three head continuous automatic box suction and opening mechanism, fast box suction speed; Accurate opening angle and strong adaptability of paper boxes

The forced pre opening mechanism avoids the phenomenon of the paper box not opening properly, improves the paper box insertion rate, and greatly reduces the number of stuck boxes. Equipped with a blowback system to blow away the paper scraps produced during the cardboard box production process, effectively improving packaging efficiency and avoiding cross door contamination

Automatic detection and control of paper box conveying speed to avoid inaccurate suction caused by loose paper box arrangement, which affects product quality and equipment stability; When the number of paper boxes in the cardboard bin is too low, an automatic alarm will prompt the operator to add paper boxes in a timely manner to avoid downtime or unnecessary waste caused by a lack of paper boxes (folding the instruction manual);

The paper box feeding bin uses servo motor control to transport paper boxes, and the number of paper boxes can be adjusted and controlled. The time for conveying paper boxes, the number of paper boxes, and the length of conveyor belt movement can be freely set. It is not easy to drop boxes, has better durability, and the conveying speed is faster and more stable.

The paper box workstation is equipped with paper box cutting detection and paper box positioning detection, effectively detecting whether the paper boxes are correctly opened and accurately positioned. If there is an inaccurate positioning, the automatic alarm will stop, and the conveyor chain will automatically separate from the main transmission system to ensure that the boxes are not stuck or damaged, greatly improving the product qualification rate.

2.8 Folding Machine

The origami machine is a matching product designed specifically for multifunctional box packing machines. It can operate continuously and provide instructions for multiple folding methods to meet the needs of multifunctional box packing machines.

Structure and working principle of origami machine: The instruction manual is stacked on the paper tray extending from the origami machine. Through a series of actions such as suction, paper separation, blowing, and paper rolling, the bottom instruction manual on the tray is rolled into the origami machine. Then, through the action of the origami roller and the paper blocking plate installed as required, the folded instruction manual that meets the requirements will be obtained at the outlet of the lower conveyor belt of the origami machine.

The manual automatic folding and conveying mechanism has high paper separation accuracy, with adjustable automatic folding for 1-4 folds. The manual conveying is accurate, and the storage space of the manual is detected. When the number of instructions is too small, the machine will automatically stop to avoid products without instructions entering the next process. The transmission mechanism of the origami machine is a synchronous wheel synchronous belt, which has a lighter sound, better stability, and is more durable than the chain wheel transmission. It is free of oil stains and more environmentally friendly.

The manual workstation is equipped with manual cutting detection, which automatically detects whether the folding output of the manual has been carried out by the folding machine. If the manual output is not detected, it will automatically feedback to the PLC and control the suction mechanism to stop suction, effectively ensuring that the paper box is not wasted.

Inspection of the instruction manual entering the box, confirming the accuracy of the instruction manual entering the paper box at the moment when the material and instruction manual are pushed into the box. If the instruction manual is not correctly inserted into the box, it will be automatically removed to ensure the product qualification rate.

3. Progressiveness of ZH-260 High Speed Automatic Cartoning Machine

(1) Simple structure, large maintenance space, few fault points, easy troubleshooting, few components, low maintenance and operation costs.

(2) The unique synchronous wheel synchronous belt connection output method is stable and reliable, without mechanical wear and lubrication, extending the service life of components and effectively reducing labor intensity.

(3) Instant card box separation and shutdown mechanism, with one card stopping immediately without damaging the paper box, easy and fast to remove, reducing packaging waste, improving work efficiency, and reducing labor intensity.

4. Technical parameters of ZH-260 high-speed box packing machine

项目 | 参数 |

设计最大生产能力 | 150-250盒/分 |

纸盒尺寸范围 | 最大160×130×50mm 最小75×50×20mm |

说明书纸张范围 | (80-150)mm×(90-200)mm(长×宽) 最小折叠宽度15mm |

电源 | 380V 50Hz 三相四线 |

主电机功率 | 2.2KW |

2.2KW | ≥0.6Mpa |

耗气量 | 0.06~0.09m³min(压力0.6~0.9Mpa) |

整机外形尺寸 | 4750×1600×1800mm(长×宽×高) |

整机重量 | 约3500Kg |

噪音 | <80分贝 |

5. Configuration List of ZH-260 High Speed Boxing Machine

260装盒机系统配置清单 | |||||

序号 | 品牌 | 产品名称 | 规格 | 数量 | 备注 |

1 | 西门子 | 10寸屏 | 6AV6 648-0CE11-3AX0 | 1 | 标配 |

2 | 西门子 | CPU ST60 | 6ES7 288-1ST60-0AA0 | 1 | |

3 | 西门子 | 电池 | 6ES7 288-5BA01-0AA0 | 1 | |

4 | 西门子 | CPU 8入8出 | 6ES7 288-2DT16-0AA0 | 1 | |

5 | 西门子 | 伺服驱动器 | 6SL3210-5FB10-4UA1 | 3 | |

6 | 西门子 | 伺服电机 | 1FL6034-2AF21-1AA1 | 3 | |

7 | 西门子 | 3米编码器线缆 | 6FX3002-2CT20-1AD0 | 1 | |

8 | 西门子 | 3米动力线线缆 | 6FX3002-5CK01-1AD0 | 1 | |

9 | 西门子 | 3米控制线线缆 | 3米控制线线缆 | 1 | |

10 | 西门子 | 5米编码器线缆 | 6FX3002-2CT20-1AF0 | 2 | |

11 | 西门子 | 5米动力线线缆 | 6FX3002-5CK01-1AF0 | 2 | |

12 | 西门子 | 5米控制线线缆 | 3米控制线线缆 | 2 | |

13 | 西门子 | 5.5KW变频器 | 6SL3210-5BE25-5UV0 | 1 | |

14 | 欧姆龙 | 相序保护器 | K8DS-PH1 | 1 | |

15 | 欧姆龙 | 开关电源 | S8FS-C15024 | 2 | |

16 | 欧姆龙 | 编码器 | E6B2-CWZ6C-600P | 2 | |

17 | MOXA | 交换机 | EDS-205 | 1 | |

18 | 威迅 | 电缆网线 | VAP-A06-S500 | 1 | |

19 | 威迅 | 电缆网线 | VAP-A06-S300 | 1 | |

20 | 欧姆龙 | 螺杆式接近开关 | E2B-M12KS02-WZ-C1 2M | 7 | 下料伺服原点2个,多料1个,少料1个,压盒1个,推杆过载1个手柄检测。 |

21 | 倍加福 | 检测光电 | ML100-8-HGU-100 | 6 | 插舌检测 |

22 | 欧姆龙 | 检测光电 | E3Z-D61 | 6 | 说明书料仓1个,说明书检测1个,盒料仓1个,盒展开1个,堵盒1个,吸盒1个 |

23 | 欧姆龙 | 检测光电 | E2B-M30LN30WZ-C1 | 1 | 空盒检测 |

24 | 思科 | 检测光电 | LUTM-UN81162P | 1 | 说明书入盒检测 |

25 | 思科 | 原装线缆 | DOL-1204-G05M | 1 | |

26 | 劳易测 | 关电开关 | 1 | 走盒检测 | |

27 | 台湾沙克 | 遥控器 | Q600 | 1 | 遥控点动 |

28 | 施耐德 | 微型断路器 | OSMC32N3C32 | 1 | |

29 | 施耐德 | 微型断路器 | OSMC32N3C20 | 1 | |

30 | 施耐德 | 微型断路器 | OSMC32N2C25 | 2 | |

31 | 施耐德 | 微型断路器 | OSMC32N1C10 | 1 | |

32 | 施耐德 | 交流接触器 | LC1E3210M5N | 1 | |

33 | 施耐德 | 交流接触器 | LC1E0901M5N | 1 | |

34 | 欧姆龙 | 继电器头子 | LY2N-J DC24 BY OMI | 6 | |

35 | 欧姆龙 | 继电器底座 | PTF08A-E | 6 | |

36 | 科象 | 信号放大器 | XSGK-DC-8N | 2 | |

37 | 魏德米勒 | 接线端子 | ZDN2.5 | 96 | |

38 | 魏德米勒 | 接线端子 | ZDU6 | 3 | |

39 | 魏德米勒 | 接线端子 | ZDU4 | 11 | |

40 | 魏德米勒 | 接线端子 | ZPE2.5 | 3 | |

41 | 魏德米勒 | 短接片 | ZQV 2.5/10 | 4 | |

42 | 地线端子 | 地线端子 | ZPE-6-25 | 1 | |

43 | 施耐德 | 按钮(红色 1NO) | XB2BA41C | 1 | |

44 | 施耐德 | 按钮(蓝色 1NO) | XB2BA61C | 1 | |

45 | 施耐德 | 按钮(绿色 1NO) | XB2BA31C | 1 | |

46 | 施耐德 | 急停 (红色 1NC) | XB2BS542C | 1 | |

47 | 自制 | 胶木板 | 350*1200 | 1 | |

6. Equipment vulnerable parts and list

序号 | 名称 | 规格 | 数量 | 单位 | 备注 |

1 | 真空吸盘 | 直径35mm | 6 | 个 | |

2 | 进口同步带 | 41齿-L-20 | 2 | 条 | |

3 | 进口同步带 | 57齿-XL-20 | 2 | 条 | |

4 | 进口同步带 | 112齿-XL-20 | 2 | 条 | |

5 | 进口同步带 | 46齿-L-20 | 1 | 条 | |

6 | 进口同步带 | 51齿-L-20 | 1 | 条 | |

7 | 进口送纸传动带 | 144- XL -28 | 1 | 条 | |

8 | 短链板 | 80×23 | 10 | 个 | |

9 | 长链板 | 150×23 | 10 | 个 | |

10 | 折纸机传动带 | HTD535-20 | 1 | 条 | |

11 | 折纸机送纸皮带 | 385×15×1 | 2 | 条 | |

12 | 折纸机送纸皮带 | 800×15×1 | 2 | 条 | |

13 | 折纸机送纸皮带 | 680×15×1 | 2 | 条 | |

14 | 折纸机送纸皮带 | 365×15×1 | 2 | 条 | |

15 | 纸夹组合 | 配套 | 1 | 套 | ZH260-12044 |

16 | 钢字 | 0----9# | 15 | 只 |

7. List of Spare Parts

序 号 | 名称及规格 | 单 位 | 数 量 | 备 注 |

1 | 0-9#钢字与间隔号(.) | 只 | 各15 | 反字 |

2 | 螺丝刀”一字”,”十字” | 件 | 各1 | |

3 | 纸夹子拉簧 | 只 | 各10 | |

4 | 内六角扳手 | 套 | 1 | |

5 | 8-10,12-14,17-19呆板手 | 件 | 各1 | |

6 | 真空吸盘 | 只 | 6 | |

7 | 折纸机输送带 | 条 | 各2 | |

8 | 出盒输送带 | 条 | 2 | |

9 | 油枪 | 只 | 1 | |

10 | 8,12寸活动板手 | 把 | 各1 | |

11 | 尖嘴钳 | 把 | 1 | |

12 | 长/短链板 | 只 | 各10 | |

13 | 说明书夹子 | 只 | 3 |

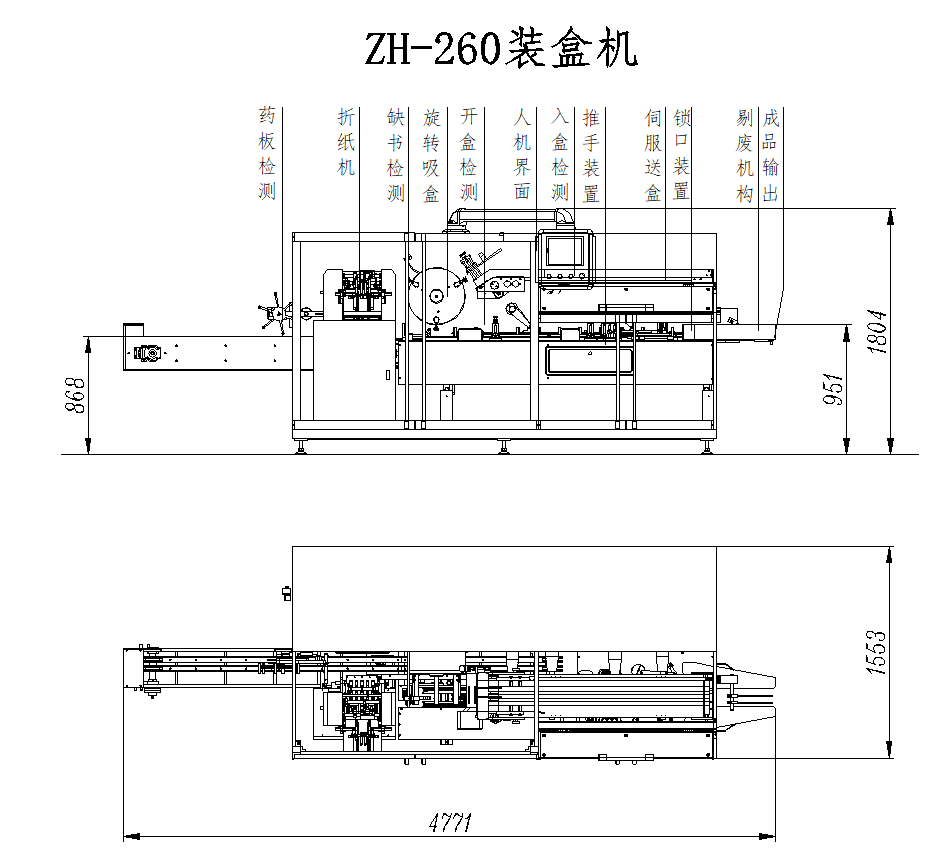

8. Equipment installation diagram

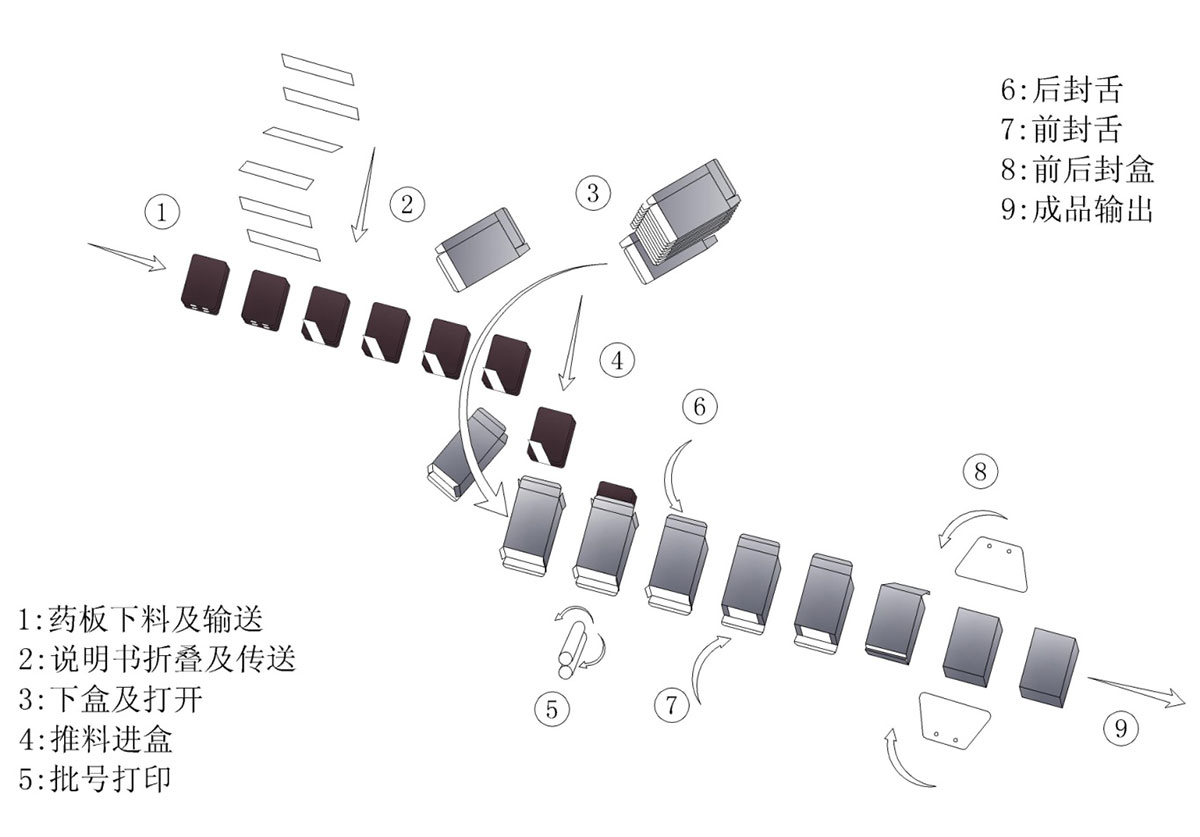

9. Machine workflow diagram

Firstly, the feeding device of the silo places the medicine board on the plate conveyor belt ① and transports it forward. When the photoelectric eye detects the medication board, the folding machine folds and transmits the instructions ②. At the same time, the lower box device waits for the arrival of the medicine board and instruction manual to lower the box and open the gentian. Then the pushing mechanism pushes the medicine board and instruction manual into the box ④. The randomizer operates, and the clamping conveyor chain transports the medicine box to the rear sealing device ⑤, front sealing device ⑥, batch number printing ⑦, front and rear sealing devices ⑧. Finally, the box is sealed and outputted by the conveyor belt ⑨.

10. Schematic diagram of machine transmission system

11. Description of each component

- Cartoning machine : Anti disassembly paper box automatic forming and packaging integrated machine 2023-09-06 11:17

- Cartoning machine : NBR-ZH-80 automatic boxing machine 2023-09-06 11:17

- Cartoning machine : NBR-200 fully automatic food spray packaging machine 2023-09-06 11:17

- Cartoning machine : NBR-200A Multi row Bag Packaging Machine 2023-09-06 11:17

- Cartoning machine : NBR-120 fully automatic box loading machine 2023-09-06 11:17

- Cartoning machine : NBR-300 pillow type automatic box loading machine 2023-09-06 11:17

- Cartoning machine : NBR-300L pillow type automatic box loading machine 2023-09-06 11:17

- Cartoning machine : NBR-130 automatic box loading machine 2023-09-06 11:17

- Cartoning machine : NBR-50 vertical packaging machine 2023-09-06 11:17

- Cartoning machine : NBR-300A fully servo automatic boxing machine 2024-03-14 14:49

- Cartoning machine : NBR-ZH-260 fully automatic high-speed box packing machine 2024-04-30 16:22